A single roller chain with its corresponding sprockets is used in most roller chain drives.

However, it is not unusual for multiple-strand sprockets to be inserted into a single hub, allowing a load to be transmitted through multiple chains, up to ten in total.

In conveyor applications, multi-strand sprockets are used to maintain a consistent pace.

Each chain and sprocket has a longer performance life when a load is distributed through several sprockets.

Multiple-strands are valuable in drives where the necessary horsepower exceeds the horsepower rating of the chain.

This is also typical in conditions where the transmission may continue to operate after a roller chain failure.

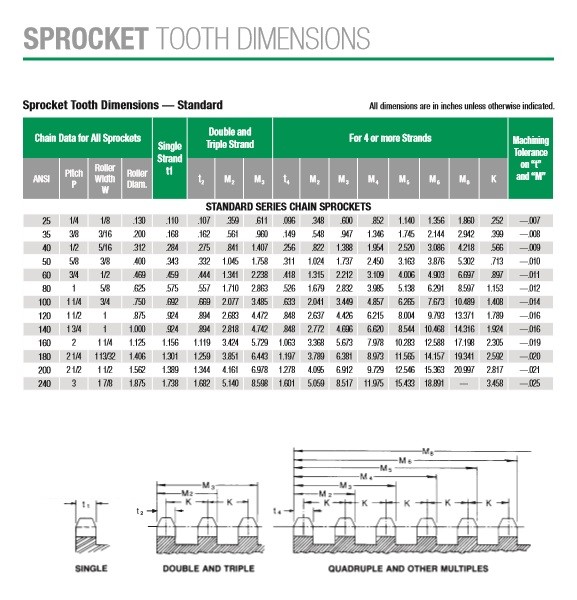

ANSI code B 29.1, which regulates chain drive design, dimensions, and interchangeability, has been adopted by North American and some Asian sprocket manufacturers.

Single-strand, double-strand, triple-strand, and multiple-strand sprockets are one of the eight strand styles covered by ANSI (4, 5, 6, 8, and 10).

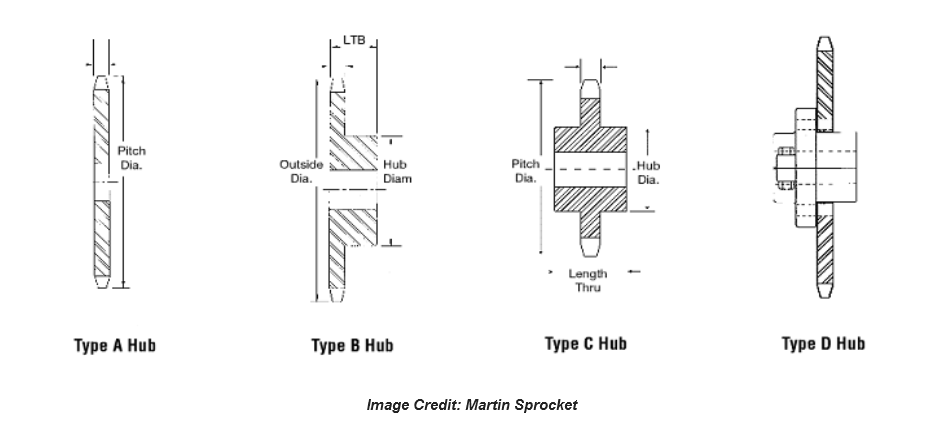

Style A – a flat sprocket with no hub

Style B – a sprocket with a hub on one side

Style C – a sprocket with hubs on both sides

Style D – a sprocket with a bolted hub attached to a plate

Sprockets which meet ANSI requirements are most often given preferred numbers, with each sprocket having assigned a number based on the tooth pitch and gap diameter.

The pitch is indicated by the left-hand digit, which is incremented in eighths of an inch.

The number’s right-hand digit indicates the type of chain to use with the sprocket, with 0 symbolizing regular chain, 1 indicating lightweight chain, and 5 indicating rollerless, bushed chain.